An oil skimmer is a device that is designed to remove oil floating on a liquid surface. Depending on the specific design they are used for a variety of applications such as oil spill response, as a part of oily water treatment systems, removing oil from machine tool coolant and aqueous parts washers, and collecting fats oils and greases in wastewater treatment in food manufacturing industries.

Belt oil skimmers are one of the most reliable and economical equipment for removing liquid surface floating oil with low electric consumption without the need for any consumable. They can effective remove all kinds of floating oil (including machine oil, kerosene, diesel oil, lubricating oil, plant oil and other liquids with specific gravity less than water. This is a versatile skimmer design, it can remove floating oil no matter what the thickness of the oil layer is.

FeaturesAdvantages Of Oil Skimmers: like ..

Application of NeoSkim :

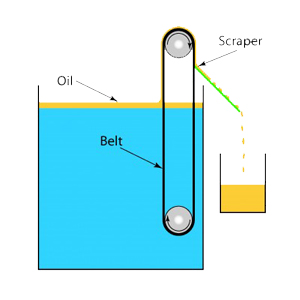

The NeoSkim Model utilizes a continuous belt and wiper to remove up to 150 liters of oil per hour from the fluid surface. The belt, operating on a motor and pulley system, runs through contaminated liquid to pick up oil from the surface. After traveling over the head pulley, the belt passes through tandem wiper blades where oil is scraped off both sides of the belt and discharged. The tail pulley has flanges which allow it to roll freely on the inside of the belt without becoming dislodged. It requires no bearings and does not need to be fastened to the tank. If turbulent conditions exist, an optional tether and cage assembly prevents the tail pulley from being dislodged.

Oil skimming makes use of the differences in specific gravity and surface tension between oil and water. These physical characteristics allow the belt to attract oil and other hydrocarbon liquids from the surface of the fluid. The NeoSkim can be used in tanks with depths as shallow as one foot, or as deep as 100 feet.

Proper oil water separator design proactively accelerates this separation process, allowing for continuous oil separation and recovery that matches the needs of industrial facilities.

Copyright © 2019 Neotechwater, Vapi - Designed by KrisTech