The corrugated plate pack in a CPI separator, used in Oily water treatment for removal of free oil. It consists number of parallel corrugated plates. A Plate pack is a housing of flat plastic plates (strengthened by resins) and stiffened by a frame made from plastic material (strengthened by resins) and/or stainless steel.

The number of plates in a Plate pack is determined by various calculations as well as based on experience on various effluents and applications. The number of plates per pack is also factored to a certain extent on economy of size of the separator. The number of Plate packs per CPI separator is calculated based on the effluent flow and its characteristics to the unit.

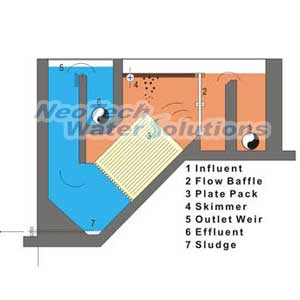

The liquid to be treated flows through the spaces between the Corrugated Plates in each Plate pack. Ideal condition for separation is achieved in the TPI (Tilted plate interceptor)/CPI (Corrugated plate interceptor) separator by simulating a laminar flow condition through the plate pack.

Gravity separation is the most straightforward method of effluent treatment and is, therefore, utilised widely in industry for the separation of settling and/or flotable impurities from a carrier liquid. In the majority of cases the separators are constructed in the form of a rectangular tank.

Advantages Of Designed TPI/ CPI Separators in Oily Water Treatment System: like ..

The most common form of parallel plate interceptor used in oil facilities is the corrugated plate interceptor (CPI). This is a refinement of the PPI in that it takes up less plan area for the same particle size removal, and has the added benefit of making sediment handling easier. Figures illustrates a typical downflow CPI design and third slide shows a typical CPI pack.

Conceptually, the oil/water separation process is simple allow oily water to sit undisturbed long enough and eventually oil globules will begin to stratify, sink or float, but this passive approach is often too slow to work in real world applications where flows and loadings are always changing.

Proper oil water separator design proactively accelerates this separation process, allowing for continuous oil separation and recovery that matches the needs of industrial facilities.

Copyright © 2019 Neotech Water Solutions, Vapi - Designed by KrisTech