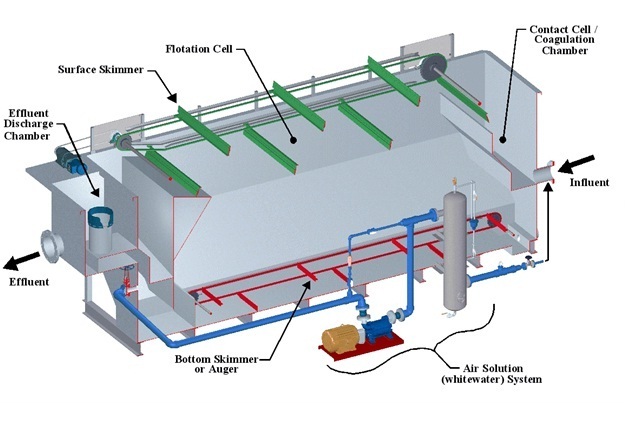

Dissolved Air Flotation (DAF) system is a proven tchnology to remove suspended solids and Oil from water. Dissolved Air Flotation System also helps to remove greases and suspended micro particles from a wastewater stream. Suspended Contaminants are removed through the use of micro air bubbles, produced by injecting air under pressure into a stream of clarified DAF effluent. This stream is then combined and mixed with incoming wastewater in an internal content chamber where the dissolved air floats out of solution in the form of micron-sized bubbles that attach to the contaminants. The bubbles and contaminants rise to the surface and form a floating bed of material that is removed by a surface skimmer and collected into an internal hopper for further handling.

Dissolved Air Flotation technology is widely used in treating the industrial wastewater effluents generated from oil refineries, petrochemical and chemical plants, natural gas processing plants, paper mills, general water treatment and similar industrial facilities. A very similar process known as induced gas flotation is also used for wastewater treatment. Froth flotation is commonly used in the processing of mineral ores works on flotation technology.

Dissolved air flotation system operates on the principal of the transfer of floc to the surface of water through Floating air bubbles in the water. The floc accumulated on the surface, known as the float, is skimmed off as sludge with countinuous process. The clarified water is removed from the bottom and is sometimes called the treated water.

The design of the Dissolved Air Flotation plant is based on the specific gravity difference between the oil and the wastewater because that difference is much smaller than the specific gravity difference between the suspended solids and water. Based on that design criterion, most of the suspended solids will settle to the bottom of the separator as a sediment layer, the oil will rise to top of the separator, and the wastewater will be the middle layer between the oil on top and the solids on the bottom.

Like all clarification processes flotation performance depends on the effectiveness of coagulation and flocculation. Polyelectrolyte dosing is often included to compensate for reduced performance at low water temperature or if the floc is fragile. Although the process has been successfully used for some directly abstracted waters other clarification methods tend to be more suitable for treatment of such waters especially when the turbidity consistently exceeds about 100 NTU.

Dissolved air flotation is one of our best products with high end technology for industries. Neotech Water Solutions is countinuously improves the quality of products with more and advance features. like ..

Waste water effected with polutant and treated with DAF. Dissolved Air Flotation System worked well and reusulted in clear water. most of all floating floc have been removed and visibly clean.

Dissolved air flotation i.e. DAF is a water treatment process that clarifies wastewaters by the removal of suspended matter such as oil or micro solids. The removal is achieved by dissolving air micro bubbles in the water or wastewater under pressure and then releasing the air at atmospheric pressure in a flotation tank basin. The released air forms tiny bubbles which adhere to the suspended matter causing the suspended matter to float to the surface of the water where it may then be removed by a skimming device.

DAF has major sections

Copyright © 2019 Neotech Water Solutions, Vapi - Designed by KrisTech