Surface aerators push water from under the water's surface up into the air, then the droplets fall back into the water, mixing in oxygen. The jets of water break the surface with varying degrees of force. There are many types of surface aeration devices, including floating aerators.

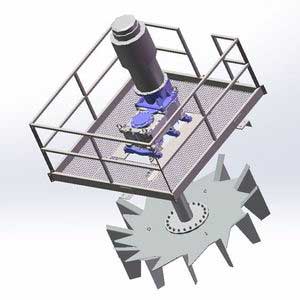

NeoMAX is the new generation Surface aerator. After a long period of testing, the ideal design was developed. A complete new design which ensures a high efficiency, a huge mixing effect and very smooth running with less vibration to the bridge and drive unit.

We are leading in manufacturing of Fixed Surface Aerator and Floating typr Surface Aerators. There are two types of aerator in our product range.

Types of AeratorApplication of NeoMAX :

In many applications of slow speed surface aerators the function of the aerator is not just limited to introducing oxygen into the water. Also, a part of the propulsion and mixing has to be provided by the surface aerator. That is one of the reasons why the characteristic conical shape is noticeable in the design of the blades. This is the source of the pump function which is necessary for creating good mixing conditions inside the basin. For oxidation ditches this results in excellent propulsion.

The design of the NeoMax is such that both radial and axial forces are much lower than with conventional surface aerators. This has many advantages. In particular, the forces on the concrete and on the bearings of the outgoing shaft of the gearbox will be much lower. Because of this, in many cases, one can select a gearbox which will be one size smaller. Also the vibration characteristics will be reduced enormously, so that critical vibrations in the gearbox will not occur.

The starting point of the design of the NeoMax Surface Aerator was not only that the available power had to lead to a higher oxygen transfer, but also that the aerator had to be easy to maintain and long trouble free life.

The design and the shape of the blades OF Surface Aerator is configured in such a way that it is impossible for any rag or other detritus to attach to the impellor. This is largely due to the virtual cone shape created by the blades.

Because the complete surface aerator unit is built up from impellor, bearing supports, gearbox and electric motor, maintenance is limited to a yearly oil check and periodical checking of all greasing points.

The selection of the size of the surface aerator is primary based on the amount of oxygen which has to be introduced into the water. The oxygen capacity can be regulated by regulating the speed by means of a variable frequency drive (VFD) and the online DO meter. The actual regulation is nearly always monitored by means of an oxygen probe.

Copyright © 2019 Neotechwater, Vapi - Designed by KrisTech